About Daftmill

Daftmill is a family farm situated in the Howe of Fife. Our main enterprises are growing cereals, mainly malting barley, rearing beef cattle and growing potatoes. The farm also produces carrots and broccoli.

In June 2003 we applied for planning permission to convert the old mill buildings into a distillery. It took most of 2004 and 2005 to repair the buildings and install all the equipment. By St Andrews day 2005 when we received our licence from Her Majesty’s Revenue and Customs we were ready to start distilling.

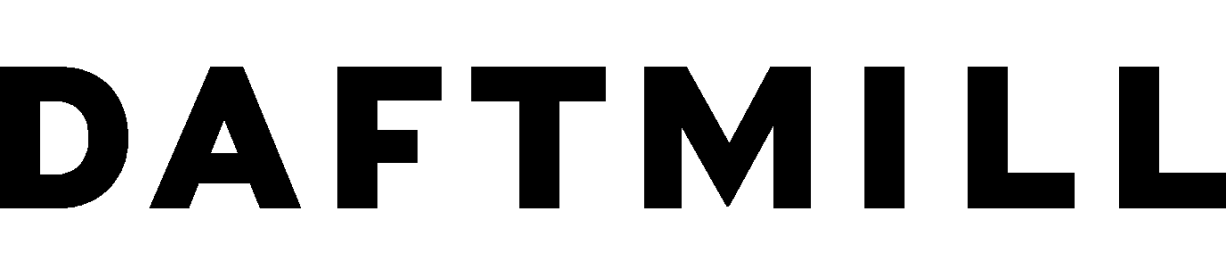

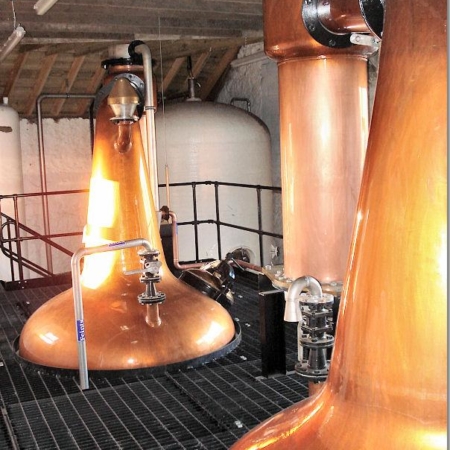

The arrival of the copper stills

Other than the stills and the mash tun which came from coppersmiths Forsyths in Rothes, all the other equipment and work to convert the buildings and create the distillery was supplied by local craftsmen from around the Cupar area.

In the distillery we use the barley that we grow on the farm and water from our own artesian well to make our whisky.

Our duck pond

The distillery operates in harmony with the farm. The farm grows the barley then after it is mashed in the spent grains or draff provide a nutritious protein rich feed for the cattle. The pot ale and spentlees, that’s the left overs from the distillation, are stored in a large tank on the farm then sprayed onto the grass or barley stubble as a fertiliser. The warm water that has been used to cool the stills is either kept to be used for the next mash or it is pumped into the duck pond where any heat is lost. It also helps stop the pond from freezing over in the Winter.

The distillery has to operate on a seasonal basis around the farming calendar. During the winter months when things are not so busy on the farm we make whisky but by spring time we need to get the barley sown, potatoes planted and cattle out to grass so the distillery falls silent. In mid-summer there is a lull in the farm work, and we distill in June and July before shutting down again for harvest time. Operating like this was once the norm but has not been seen in Scotland for the last 100 years.

The Distillery

In 2003 brothers Francis and Ian Cuthbert applied for planning permission to convert the old mill into a distillery.

We tried to ensure that the project was an entirely local affair and were keen to see that all the work was carried out, where possible, by people living close by to the farm. Apart from the copper stills, which were made in Rothes, we ensured all the work has been carried out by people within a five mile radius of the farm.

The license to distil was granted by Her Majesty’s Revenue & Customs on St Andrews Day 2005 and the first whisky was produced on 16th December 2005, making Daftmill the newest distillery to open in Scotland at that time.

The Angels’ Share

Scotch whisky has to be at least three years old before it can be sold. At Daftmill we anticipate that our whisky will be at least 10 years old before coming to market.

During this time it stays in the bond where every day some of the alcohol evaporates, reducing the strength of the whisky and making it more mellow.

This evaporated alcohol is known as the “angels’ share”.

The Water Tower

People often remark on our water tower which stands out and is a local landmark.

Family history has it that the tower was built by a Dutch architect/engineer who was across here for the building of the Tay Rail Bridge, hence the Dutch appearance. The Walker family who owned the estate at that time were investors in the railway so the story is certainly possible.

The Tower has a large water tank at the top which provides the head to supply our water by gravity. The water from the artesian well used to be pumped up to the tower with a wind pump. These days, we use an electric submersible pump.

The tower has had a bit of a face lift recently, with repairs to the roof and a fresh coat of paint on the exterior. It is lasting well for being over 100 years old.

Obviously our water supply is very important to us so it pays to look after it.